Every day, we have great conversations with people who are looking to find the right 3D scanner to help them solve work-related challenges—from quality managers who are looking for a computer-aided inspection system, to archaeologists who want to preserve ancient artifacts into digital formats.

We find a majority conduct their own research before contacting us. There are times when they have already decided on whether to get a stationary or handheld 3D scanner before realizing one might be better suited for their applications after talking with us.

How do you know if a stationary or a handheld 3D scanner is most suited for your needs?

Before you decide, let’s take a look at the two options and the various factors that will influence your decision.

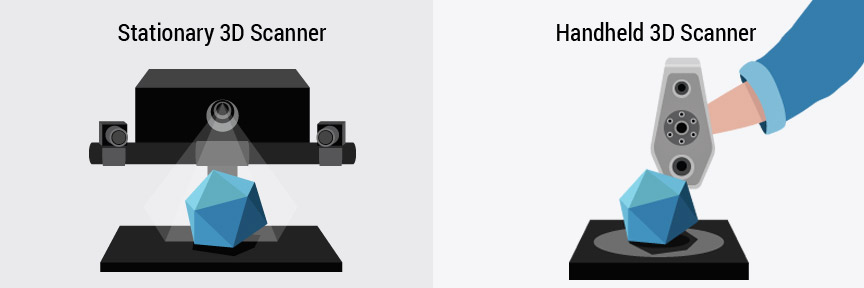

How Stationary and Handheld 3D Scanners Work

A stationary 3D scanner is mounted to an arm or a tripod and it’s fixed at a location. The user turns the object, the scanner captures a scan, and this process continues until all scans are captured of the entire object at various angles. Depending on the processing software, some can automatically merge the scans together during the scanning process or this might be done when all the scans are collected at the end. Individual scans are later stitched together to create one complete digital model.

For a handheld 3D scanner, the user hovers and paints around the object in order to obtain 3D scan data of the entire object. It operates similar to a video camera but it captures objects in 3D with continuous scanning.

Factors to Consider

-

Accuracy and Resolution

Currently, if you are comparing a stationary 3D scanner to a handheld using the same technology (e.g. structured-light), stationary 3D scanners provide better accuracy and resolution. If your application needs to drive the best possible accuracy and resolution you can get and it’s the most important factor you need in a scanner, stationary 3D scanners would be a good choice.

The scanner’s scan quality is influenced by how it works. For example, stationary 3D scanners using structured-light technology take a series of images in one snapshot and consolidates the average to generate one scan. Handheld 3D scanners using structured-light technology take one shot per frame (equivalent to one scan) and then the user moves the scanner to take another scan. It’s similar to comparing a still image taken from a camera versus a frame taken from a video recording. The former will get you better quality than the latter. The scan quality is still great for a handheld 3D scanner, but typically the stationary 3D scanner provides slightly better results when comparing scanners that are similar in price point.

However, it’s important to remember that a majority of applications don’t require the high quality. There are other factors such as portability and ease of use that might be more important to you. A handheld 3D scanner is a great solution for reverse engineering, 3D visualization, and even quality inspection applications if you don’t require the absolute best accuracy and resolution you can find.

-

Portability

Handheld 3D scanners are synonymous to portable 3D scanning. These scanners give you maximum portability compared to a stationary 3D scanner.

You can essentially take them anywhere. For example, Artec 3D scanners support battery operation for scanning offsite in the field for up to 6 hours, even in areas with no electricity. It even supports the use of a tablet to power its 3D scanning software so you don’t have to carry a lot of heavy equipment for your travel.

A stationary 3D scanner requires a desktop computer or laptop to power the 3D scanning software for data acquisition and post-processing, so you would require electricity to run the system at all times.

-

Scanning large volume of objects with a repeatable process

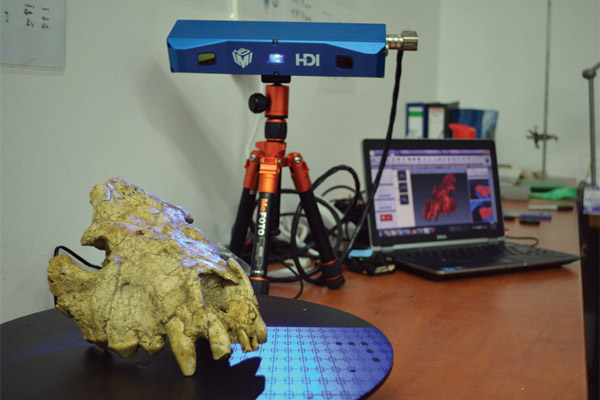

Automating the 3D scanning process of converting fossils into 3D digital format to capture surface measurements for a research study. Stationary 3D scanners are a great option if you need to scan similar sized objects in volume quickly. It enables an automated standardized setup without the need for much human involvement to help gain efficiency in the scanning process.

Automating the scanning process with a stationary 3D scanner is possible when paired with a motorized rotary turntable accessory. The user sets the rotary table to capture a certain number of scans while it spins the object in 360 degrees horizontally. When the rotary table stops spinning at certain intervals, the scanner captures a 3D scan of the object at that particular angle. Once it captures all the scans, the scanner automatically post-processes the scan data by merging and stitching all the scans together into a complete digital 3D model.

Once the object is completely scanned, the next object would be placed on the rotary table and the process starts all over again. An assembly line workflow to 3D scanning takes out much of the manual labor-intensive work.

Using Handheld 3D Scanner For Robotic Scanning

Compared to a stationary 3D scanner, a handheld 3D scanner is normally setup so the user holds the device while scanning. Because human factor is involved, it would be difficult to replicate the exact process every time you scan a set of similarly-sized objects. However, handheld 3D scanner manufacturers are starting to give users an automated, hands-free option with robotic 3D scanning.

Instead of operating the handheld 3D scanner manually, the scan head is mounted to a robotic arm programmed to move automatically. The scanning station would do it faster and more accurately than if a person is scanning by hand. Robotic scanning is also an option if you are using a stationary 3D scanner.

-

Scanning hard to reach places

It’s easier to maneuver a handheld 3D scanner compared to a stationary 3D scanner because the scan head is portable. You can easily scan holes or undercuts that would be more challenging to scan with a stationary 3D scanner.

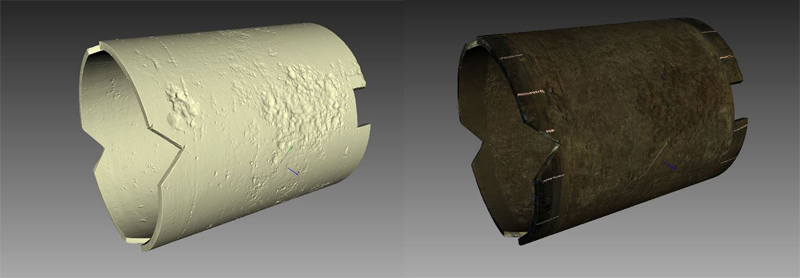

Using the Artec Eva to scan a water pipe to determine its corrosion levels.

Final digital 3D model of the water pipe. Comparing the 3D models from before and after the corrosion enables corrosion levels to be mapped to a good level of accuracy.

Handheld 3D scanners also great for scanning in confined spaces where the object, such as museum sculptures, cannot be moved to a different location for scanning. This scenario would be difficult for a stationary 3D scanner to be placed at a certain distance for scanning, where there isn’t ample space.

-

Field of view

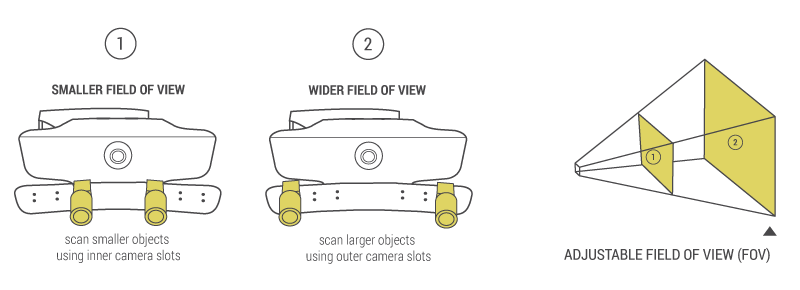

There are certain stationary 3D scanners in the market where one system is capable of scanning objects of different sizes by adjusting the scanner’s field of view (FOV). Depending on the object size you’re looking to scan, the scanner’s cameras and lenses can be moved to different mounting positions to adjust the FOV.

Field of view (FOV) is the observable area that a 3D scanner can capture a

3D scan at a certain distance. HDI Advance 3D scanner scans objects of different sizes by changing the scanner’s FOV.Handheld 3D scanners have a fixed FOV so it is restricted to the object size it can scan while retaining its accuracy.

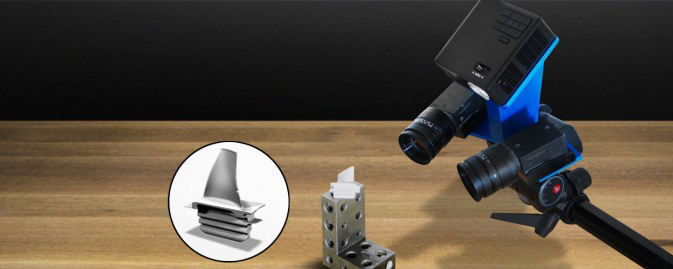

Using the HDI Advance 3D scanner as an example, if a drastically smaller field of view is required to scan an object such as small turbine blade, screw, or small insect with high precision accuracy, the scanner is flexible to be converted into a macro scanner. All you need is to use an add-on accessory kit without the need to purchase an entirely new system. If you need to scan objects that vary in a range of sizes, stationary 3D scanners might be the most cost-effective solution for your needs.

A standard HDI Advance 3D scanner is transformed into a macro 3D scanner for scanning small parts.

-

Ease of Use and Training

We train our customers on both types of scanners. Overall, the handheld device is an easier technology to pick up and to learn. It requires a shorter learning curve compared to a stationary 3D scanner.

However, if you are striving for high accuracy and resolution in your 3D scans, it takes more knowledge and training to achieve these results. It’s worth spending more time on training to use a stationary 3D scanner because you want to get optimal performance the equipment has to offer.

Get Expert Advice

Our goal here is to provide some general guidelines to help you start thinking about what factors are most important when deciding on which option is right for you.

It’s always a good idea to contact a reputable 3D scanner solutions provider who can understand your application, what you are looking for in a 3D scanner, and walk you through the different options available. They can also give you a demonstration of the stationary and handheld 3D scanners to help you ultimately make an informed decision.