Casting, a historic manufacturing method dating back to around 4000 BC, is used to produce a wide variety of intricate parts and goods. There are different types of casting processes, such as sand casting, die casting, centrifugal casting, and investment casting. The output of the casting process is used by various industries, including automotive, aerospace, construction, jewelry, and consumer goods.

While casting manufacturing practices have stood the test of time, incorporating 3D scanning can modernize each step of the process, boosting operational efficiencies and streamlining workflows to achieve significant time and cost reductions. Stay ahead of the curve and lead innovation in the casting industry with the use of 3D scanning.

Small to large objects

Metals, ceramics, plastic, rubber, concrete, etc.

Simple, prismatic, organic, intricate, or complex parts

Making a digital twin of a physical part

Storing numerous molds or bucks (replicas of parts) can consume substantial warehouse space, especially when the production of some components are infrequent.

Rather than physically housing them in a large warehouse, using a 3D scanner like the Artec Space Spider or Artec Leo to capture and create digital 3D models from physical, real-world objects is a cost-saving solution. This eliminates the necessity of maintaining a physical inventory, tremendously reducing your storage budget annually.

You can access the digital record of each component at any time. When you need a measurement in the future, there’s no need to manually remeasure the part because it’s digitally archived.

Save a significant amount of money every year by eliminating the need for a warehouse to store an inventory of components, molds, or bucks as references for future productions.

It’s easier to manage part storage now that everything is stored digitally, even if you have hundreds to thousands of parts.

3D scanners can rapidly digitize a casting component in minutes, saving tremendous time if you have to scan in volume.

You can use measurement data you can trust to make important decisions. (i.e. Artec Space Spider handheld 3D scanner has up to 0.05 mm 3D point accuracy.)

Handheld 3D scanners offer added convenience as you can bring the scanner to the part (not the other way around), especially for extra-large and heavy castings. With the Artec Leo, it’s a wireless 3D scanner with its own processor. Scan without tethering to a computer for true mobile freedom.

Want to Learn More About How 3D Scanning Can Help You With Your Casting Application?

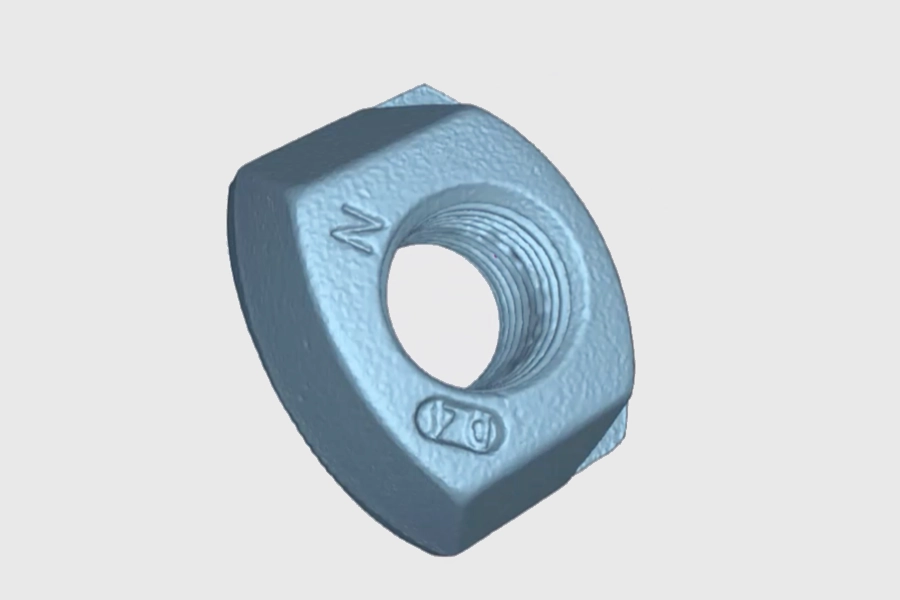

Capture part measurements for CAD workflows

Taking measurements manually with hand tools often yield inaccuracies and is a time-consuming process.

Redesigning parts that are no longer in production or CAD has become effortlessly simple. With a 3D scanner, capture data from existing parts with utmost precision and accuracy. The data serves as as a reliable reference for the new design. Using 3D scanning eliminates errors, inconsistencies, and the time-consuming nature of manually measuring parts. The part’s scan data can be seamlessly integrated into Geomagic Design X and SOLIDWORKS for reverse engineering (Mesh2Surface for SOLIDWORKS plugin for Scan to CAD conversion).

An manufacturer and distributor of construction machine spare parts used an Artec 3D scanner to achieve these results.

Each part (around 3 meters long) took 30-40 minutes to scan in detail (including the top and bottom areas).

| ROI on Reverse Engineering | Traditional + CAD | High Speed 3D Scanning + CAD |

|---|---|---|

| Method |

Manual MeasurementUsing measurement tools including measuring tape, calipers, angle meters, and protractors, and thread gauges. The final drawing is created in CAD software. |

Precise Digital Measurement with 3D Scanning3D scanning each part in detail, top, and bottom. 3D data processing in Artec Studio and CAD conversion using Geomagic Design X. |

| Time | ~ 2 weeks to complete each 3 meter part + production time |

11 hours total: 30-40 mins to scan each part, 3-4 hrs to create 3D model, 7-8 hrs to convert to solid models |

| Cost | ~80 hours at $50/hour = $4,000 | 11 hours at $50/hour = 85% cheaper than the manual method |

| Accuracy | Since the parts are difficult to measure by hand, it is prone to high risk of inaccuracies |

Up to 0.1 mm 3D accuracy (Artec Eva) |

With 3D ScanningThe manufacturer achieved 85% time and cost reduction |

||

Compare part measurements to CAD

Manual measurements yield imprecise and inconsistent results, with variations depending on the individual taking the measurements. Obtaining accurate measurements, particularly from intricate or organic parts, poses a significant challenge.

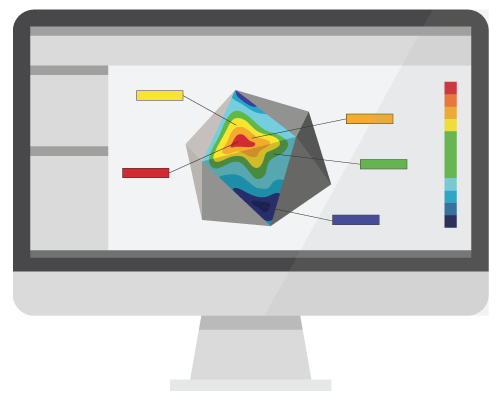

Once a casting is digitized into a 3D model, it can be compared to its original CAD file, providing a rapid inspection of all surface measurements to ensure that castings meet tolerance. Artec handheld 3D scanners capture more than 1-35 million data points per second, with 3D point accuracy of up to 0.05-0.1 mm (depending on the scanner). When combined with 3D inspection software like Geomagic Control X, it can identify the source of errors in areas of castings linked to uneven cooling. Empowered with this information, you can adjust production methods, resulting in lower production losses in time and materials.

Some castings that would have taken more than 7-10 days now being finished in 6-10 hours.

Source: Artec Case Study: How one foundry uses “crazy efficient” Artec Eva to slash up to 75% off production time, cut losses, and more.

Select a time that works best for your schedule. For your convenience, the demo time will be confirmed immediately after you submit your request.

Currently available for bookings anywhere in the USA