How do you get patients’ measurements quickly while not being invasive?

Is there a quick, easy, and accurate way of measuring complex freeform shapes like body parts?

How do you create custom-fitted products for patients that makes them feel comfortable?

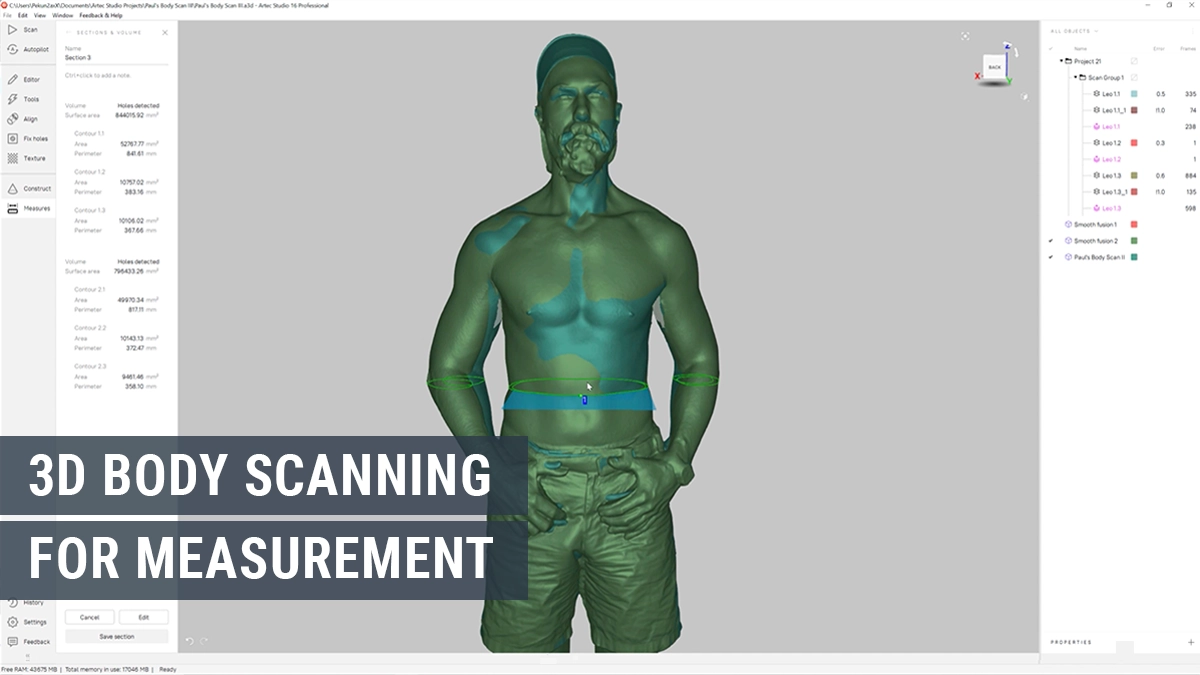

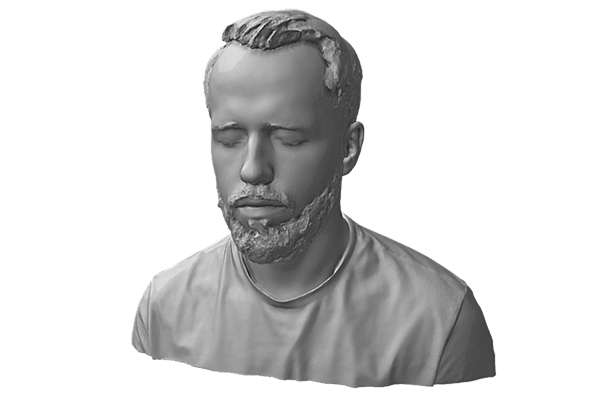

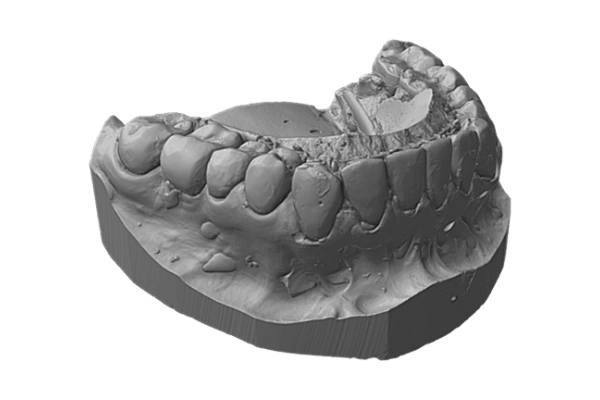

3D scanners acquire accurate body measurements quickly with many professional systems capturing more than 1 million measurement data points per second.

You can use measurement data you can trust to make important medical decisions and correctly diagnose patients. Artec 3D scanners can get accuracy of up to 0.01 mm.

This measurement method is non-invasive. No contact is made during the scanning process, making it more comfortable for patients.

It is easy to keep track of a patient’s progress over time with digital data. There’s no need to call the patient in for measurement if you already scanned the entire body or body part. Access digital records at any time.

Instead of shipping physical casts which is very labor intensive and expensive in the long run, reduce cost and save time by sending measurement records digitally in an instant.

Prosthetics and orthotics become an extension of your patient’s body. Create customized products for your patients that makes them fit and feel their best.

Compared to other conventional measurement methods, handheld 3D scanners allow for much greater flexibility in full body scan analysis and related applications due to faster data capture rates and data processing.

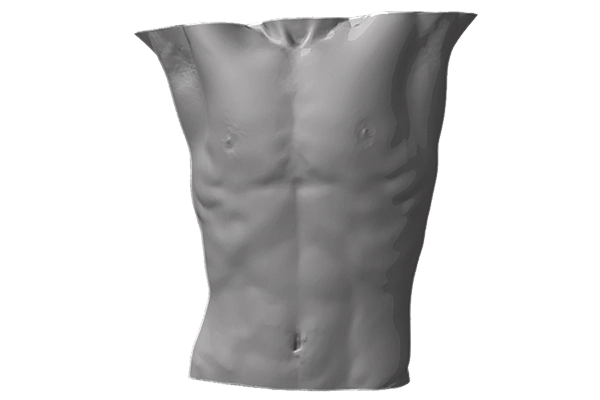

Our team demonstrates a 3D scanner’s ability to measure the human body and monitor changes over time (before and after a workout) using the Artec Leo handheld 3D scanner. By repeating these scans at regular intervals, the practitioner has the power to monitor a person’s anatomical changes and explore more advanced analysis of the body.

Anthropometry and obesity programs

Patient diagnosis by monitoring bodily changes over time

Monitor patients pre/post surgery results

“3D scanning with the Artec Leo captures a person’s precise body measurements and dimensions in less than one minute for their entire body, resulting in a color, submillimeter-accurate 3D digital twin of their body at that exact moment in time.”

– Anna Levadnaya, MD

When we think of body scanning, our minds tend to think of recreating a digital 3D model of the entire body. Body scanning applications goes beyond that. It also applies to 3D scanning specific body parts including the head, ears, hands, bust—and even bones and organs. One of the challenges of scanning people is that it is difficult for us to hold still long enough to scan. Movement in the subject during the 3D scanning process causes inferior scans. The good thing is that handheld 3D scanners offer the flexibility to scan body parts very fast with accurate results.

Head and Face

Ears

Hands, Arms, Feet and Legs

Teeth

Torso

Want to Discover How 3D Scanning Can Help Your Medical Application?

* Scan data produced by Artec 3D scanners

With 3D scanning, you can. It can make a difference in your patients’ lives every day.

Wearing an additional piece of equipment is a lifestyle adjustment. Having prosthetics, orthotics, helmets, or masks that have the right fit make patients feel better about themselves. 3D scanning empowers medical practitioners to take accurate measurements to make custom medical products that properly fit patients.

* Images source: Artec & Sanitätshaus Klinz

Discover how Artec 3D professional handheld scanners can be used for pioneering medical applications and creating customized healthcare solutions. See real examples in orthotics and prosthetics of how cutting-edge technology can dramatically improve patients’ quality of life.

Casting and measuring casts of patients’ feet is messy, laborious, and time-consuming. The manual process of creating a cast creates a less than ideal experience for patients. On the other hand, 3D scanning is fast and accurate, saving time and money, and the 3D models are easily archived for future use, unlike bulky plaster casts.

| ROI per Orthosis | Traditional + CAD | 3D Scanning + CAD |

|---|---|---|

| Method |

Manual Measurement

|

Precise Digital Measurement with Artec Eva

|

| Time | 5 hours | 1 hour (80% less time) |

| Cost | Full cost | 69% cheaper |

With 3D ScanningThe clinic achieved 80% time and 69% cost reduction |

||

* These numbers are based on a case study of an orthotics & prosthetics clinic that needed to reduce the time and costs required for creating custom orthoses, while making them more precise and comfortable for its patients.

Using 3D scanning, you can make the process much easier on your patients than traditional methods.

The treatment for microtia, a condition where a child is born with a malformed or missing ear, had been the same for almost fifty years. Conventional rib cartilage ear reconstruction is a complicated procedure that often requires two to four surgeries, long recovery times, painful to the patient, and often yield undesirable outcomes. The traditional approach can’t fully recreate a complex and delicate structure of the natural ear. Not satified with the status quo, Dr. Sheryl Lewin went in search for a better surgical option.

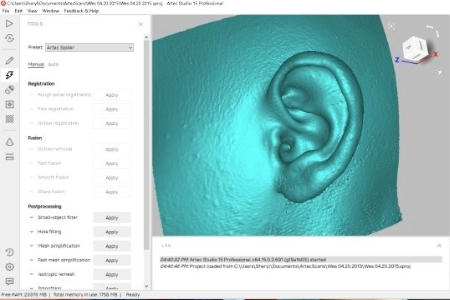

Dr. Lewin was the first surgeon in the world to revolutionize the way children born with microtia are receiving ear implants since 2019. Incorporating the use of 3D scanning technology complements her specialty. In under a minute, the patient’s “normal-sized” ear is 3D scanned with the Artec handheld 3D scanner in under 60 seconds. Using the 3D digital data file, an ultra-realistic high-density porous polyethylene implant of the mirrored image of the normal-sized ear is created for the smaller, malformed ear. In just one or two surgeries, the patient will have an ear implant that will last a lifetime.

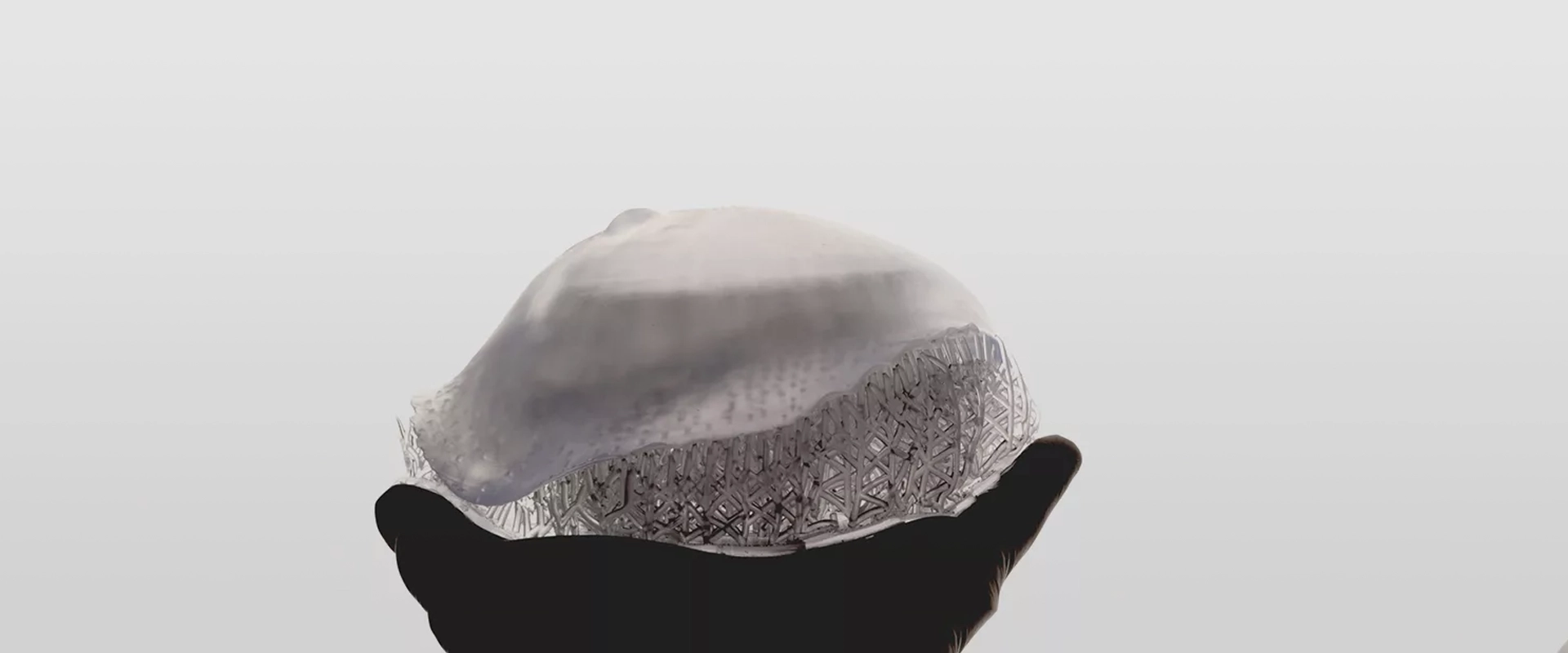

A patient normal-sized ear is scanned using Artec 3D scanner. The 3D scanning technology is 100% safe for children.

The Lewin ears are high-density porous polyethylene implant of the mirrored image of the normal-sized ear.

Before and after surgery of a child that underwent Dr. Lewin’s treatment.

Breast cancer survivors who have undergone mastectomy can now create personalized breast prostheses, crafted to ensure comfort, balance, and confidence.

Unlike traditional methods that involve covering the patient’s face with plaster, 3D scanning eliminates the need for physical contact. By utilizing CAD software, a custom-fit face mask can be 3D printed, ensuring optimal protection without causing any harm to the patient.

* Images source: Artec and Lewin Ear Reconstruction