For most reverse engineering applications, the critical information you need is the object’s surface geometry (shape) and 3D measurements (dimensions). That’s why it’s perfectly fine to reverse engineer a part using monochrome (black and white) 3D scan data.

However, sometimes you want to take advantage of using color scans when it comes to converting scan data to CAD. After doing this for many years, it’s one of the tricks we picked up to make work easier—and faster.

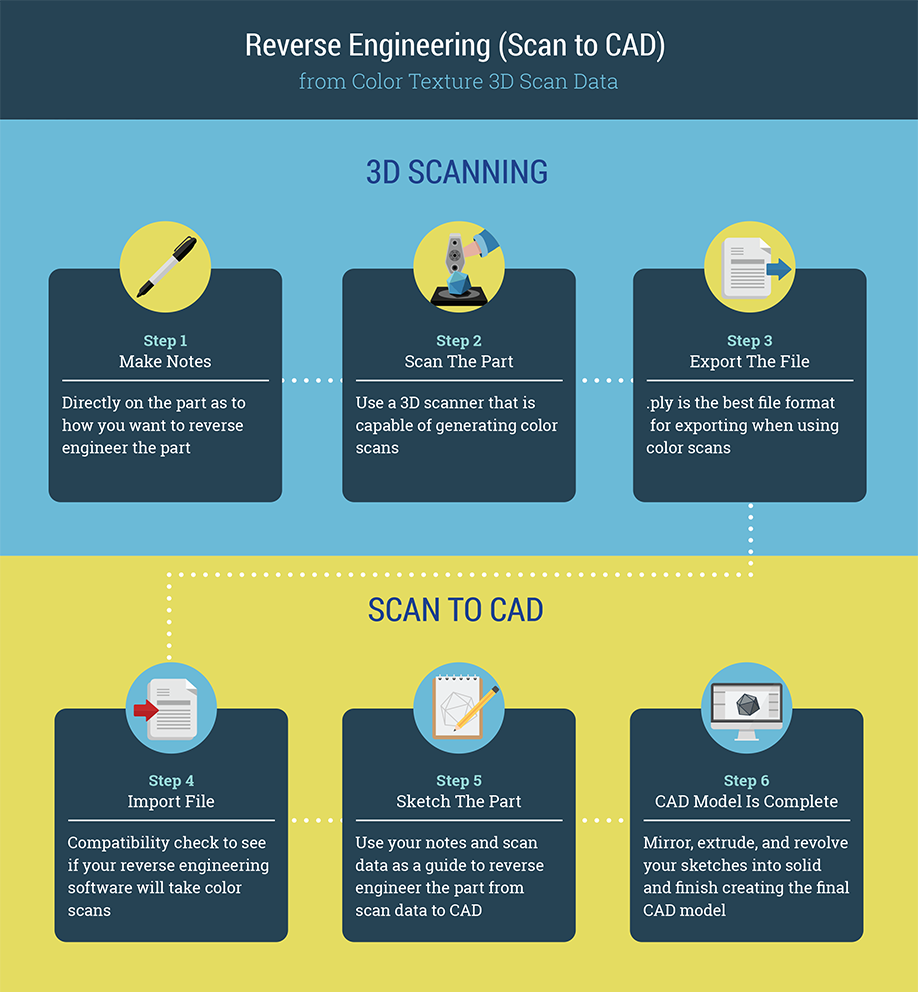

Process At A Glance

Here’s a quick step-by-step infographic to summarize the process. We’ll go into more details later.

Why would you want to reverse engineer a part using color texture 3D scan data?

-

Store all information (including your notes) in one place

You can jot down all the notes directly on the part as to how exactly you want to reverse engineer and then 3D scan the part in color. Then you don’t have to keep notes in a separate document or store it somewhere else. This is a great way to keep track of your notes all in one location since it’s directly embedded into your scan files.

All you have to do is to keep track of one file. It maximizes efficiency and makes you that much more organized.

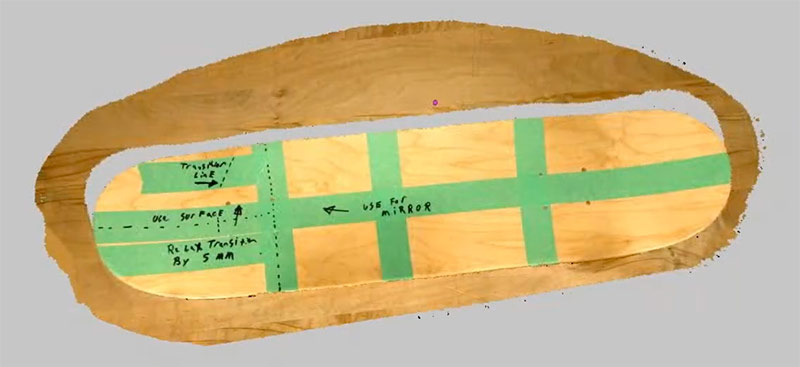

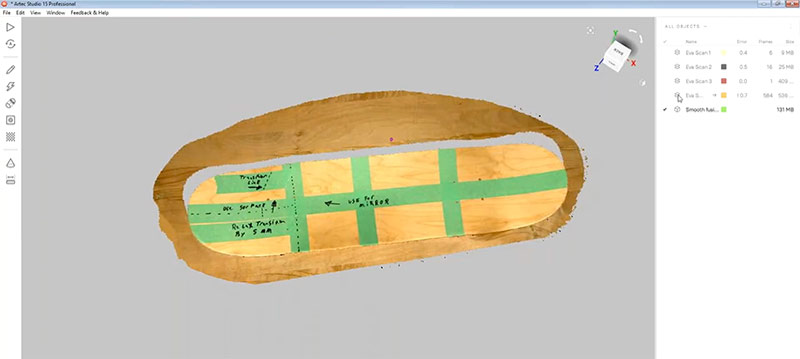

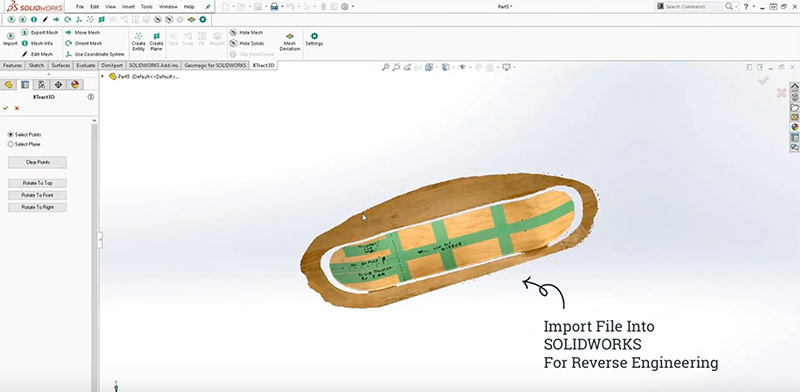

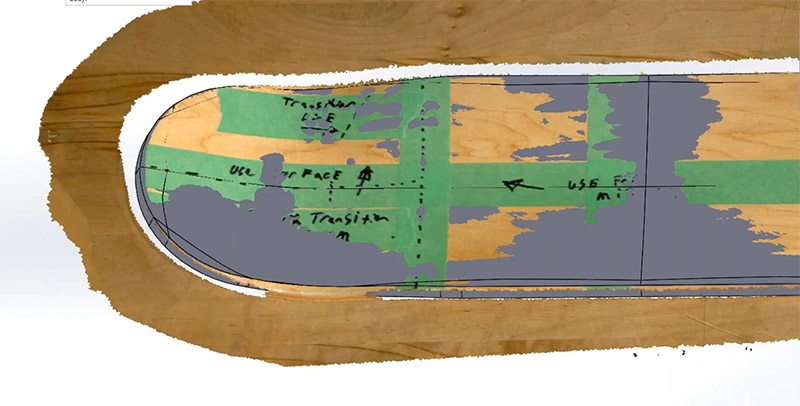

Here, we captured 3D scan data with color and texture information using the Artec Eva 3D scanner. As you can see, this gives us a roadmap by detailing exactly what modifications are needed before 3D scanning.

-

Makes it easier to reverse engineer symmetrical parts

Let’s say you are reverse engineering a turbine blade and you have a preference as to which section you want to use and the way you want to reverse engineer it. It’s much easier to keep track of the exact area you want to use if it’s already written down directly on the part. Then you can get straight to work when you import the color scan file into your reverse engineering software for converting scan data into CAD.

-

When you have to reverse engineer multiple parts at the same time

Using colors scans is ideal when you need to reverse engineer in volume. You might want to do all the scanning portion first. This helps streamline your workflow. By capturing color scans, you keep all the notes together for each file per object. You can store the files for later use when you can convert the scan data into CAD at a later time.

-

You need to do 3D scanning off-site

Using color scans for reverse engineering from scan to CAD is especially great if you have to do 3D scanning at a different location. You still have all the notes you need right there when you reverse engineer the parts back at the office.

-

You work part of a team

You might have a 3D scanning technician that does all the scanning portion of the project and another colleague who does the CAD modeling portion of the project. This is an easy way for the 3D scanning technician to make notes for the CAD specialist. To facilitate better communication across team members, the file provides visual cues as to which areas need special attention without the need to explain everything in person.

-

Great for long-term projects

If there is a long pause between the time you scan the part(s) to the time you actually reverse engineer the part(s), using color scans is a great way to ensure you don’t lose track of your thoughts when it’s time to do the actual work.

How to reverse engineer a part from scan to CAD using color 3D scans

Here, we’ll use a very basic part, a skateboard, as an example to simplify and explain the process. If you prefer to watch the entire process on video, here is the demo:

Step 1: Make notes on how you want to reverse engineer the part

We find the best way to write down your notes on the physical part is to use painter’s tape. This prevents from damaging or marking up the surface. We typically use arrows and dotted lines to define which quadrant we prefer to use to reverse engineer the part.

Step 2: Scan the part

Handheld 3D scanners like the Artec Eva, Space Spider, or Leo are perfect for this job because they capture color texture information and use color to align scans into a digital 3D model. Here you would scan the part as you typically would for any project.

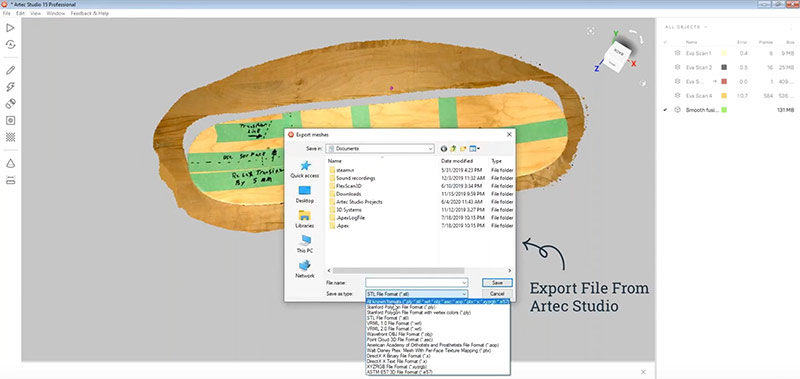

Step 3: Export the file

Before you export the file, you can clean up the scan data first if you wish. Then export the model into a suitable file format that would be accepted by your reverse engineering software or your CAD software that supports scan to CAD conversion. You can then begin the CAD creation portion of the project.

What is the best file format for exporting?

To keep the workflow as simple as possible, we find the best file format to use for reverse engineering using color scans is .ply. The reason is if you use other file formats like .obj, you would need an accompanying file such as a .mtl as well as a .jpg or .png to generate the texture of your object.

When you are dealing with reverse engineering, there is already a lot of work that needs to be done. Anything you can do to keep it as simple as possible is a bonus.

Compatibility Check

Some reverse engineering software works with color scans and some don’t. Check to see if your program of choice accepts 3D color scan files.

Step 4: Reverse engineer the part

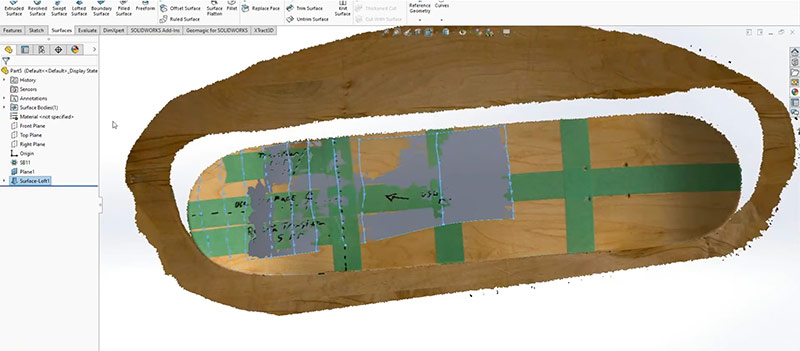

Because we wanted to create a parametric CAD model, we use SOLIDWORKS to reverse engineer the part with the help of a plug-in to convert scan data into CAD.

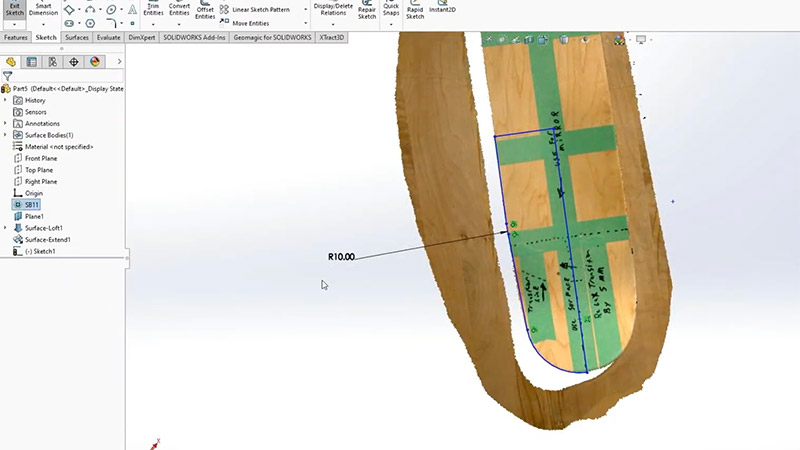

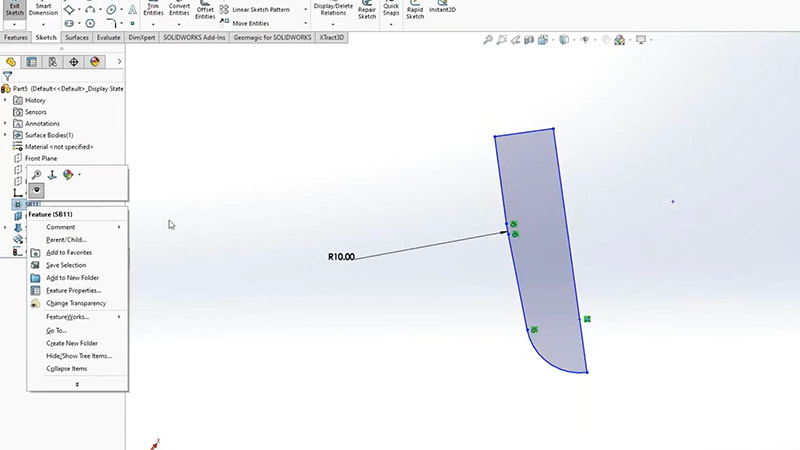

Here, we used guide curves as a reference for creating lofted surface.

A sketch of the preferred quadrant is completed using the color scan data as a reference for design.

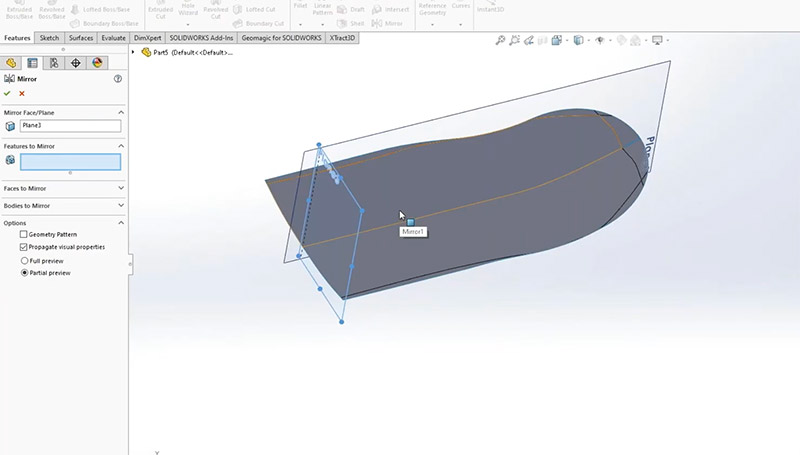

Planes are defined to mirror the surface.

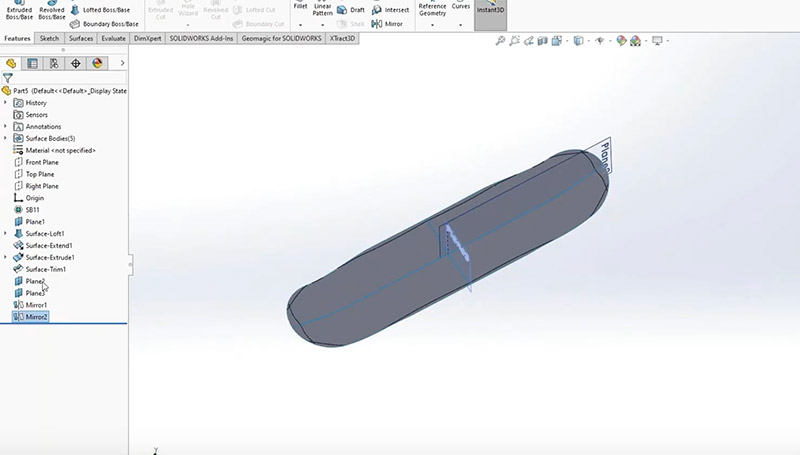

It was mirrored once again to create the overall surface.

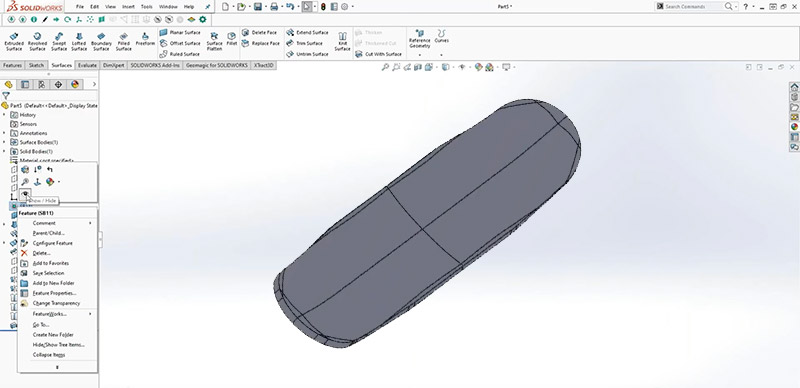

Convert the surface into solid and the CAD model is complete.

3D scan with color texture layered on top of the final CAD model.

Takeaway

While using color scans is not necessary for most reverse engineering applications, our example illustrates the benefits of using them.

Reverse engineering is already a complicated and tedious process. Using your notes together with the scan data as a guide makes the reverse engineering workflow much simpler compared to designing from scratch or using hand tools.

Got Questions?

If you have any questions about this process, or how 3D scanning technologies can help transform the way you work please feel free to reach out to us.