Multi-purpose 3D CAD software for direct modeling

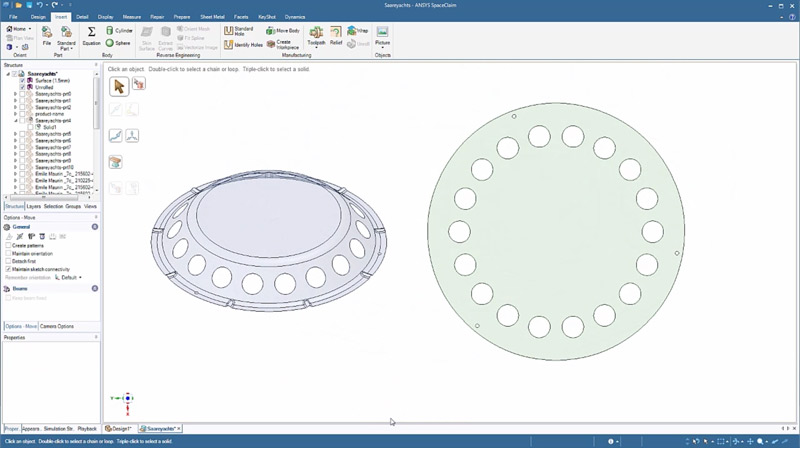

Discovery SpaceClaim is a leading software for direct modeling of manufactured parts. It provides an intuitive way to create, edit, and repair 3D models without worrying about the underlying technology.

Traditional featured-based CAD software can be expensive, rigid, and require a CAD specialist to run the program. However, most of the time a direct modeling software like Discovery SpaceClaim gets the job done—faster and simpler. Discovery SpaceClaim is a direct modeler that gives any engineer, designer, and machinist the power and flexibility to create and edit CAD models with ease.

Watch SpaceClaim Video TourDiscovery SpaceClaim has the following benefits when compared to traditional CAD software packages:

Streamlined tools and workflows empower you to immediate create rough concepts, detailed designs, tooling/fixtures, CAE related geometry, or reverse engineering STL file into clean 3D CAD model.

Think of SpaceClaim as your multi-purpose CAD modeling software. The same powerful tools are used across different use cases, regardless of complexity or scope of the modeling tasks you encounter.

Anyone can create, edit, or repair geometry without worrying where the file originated from. Import and integrate any geometry all inside SpaceClaim. Automated repair tools quickly heal dirty and incomplete CAD files.

Remove the CAD bottleneck in your workflow by bringing CAD modeling in-house. You forgo the need to outsource projects that can be expensive and have long lead times.

With Discovery SpaceClaim, you don’t need be CAD experience to get started. It has a short learning curve so you can learn as you go with minimal training.

Manipulate geometry faster and easier in SpaceClaim. Spend less time struggling and more time on productive work.

Ansys 19 Discovery SpaceClaim (previously called SpaceClaim and now a part of the ANSYS Discovery Line) is packed with improvements, making it even easier and faster to concept model and design. The newly enhanced core modeling technology helps improve navigation through assemblies and for constructing blended features quickly. The latest version will speed up your workflow in design, reverse engineering, manufacturing, 3D printing, and simulation.

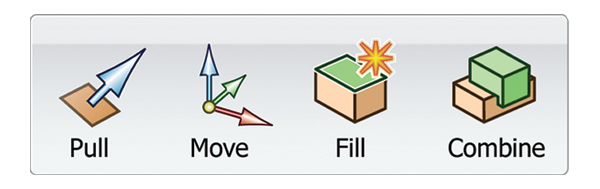

Discovery SpaceClaim doesn’t require you to have any specialized skills in order to create or edit CAD models. Easily create and modify features with four modeling tools: pull, move, fill, and combine. You can perform 80% of the common modeling tasks using these 4 tools. While feature-based approach to modeling can confine you from editing the models later on with a lot of complexities, SpaceClaim’s direct modeling approach helps you modify designs at a later time if needed, without restrictions.

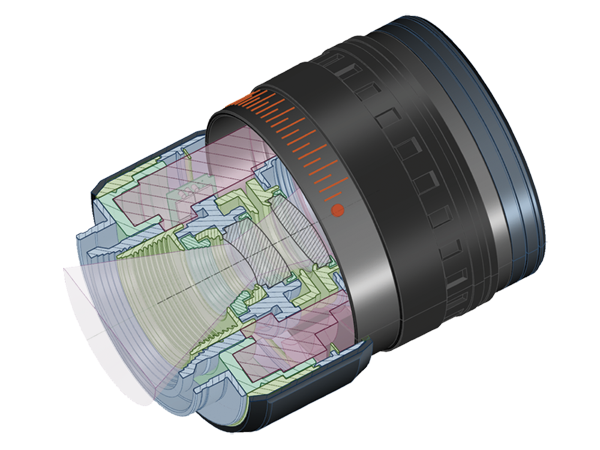

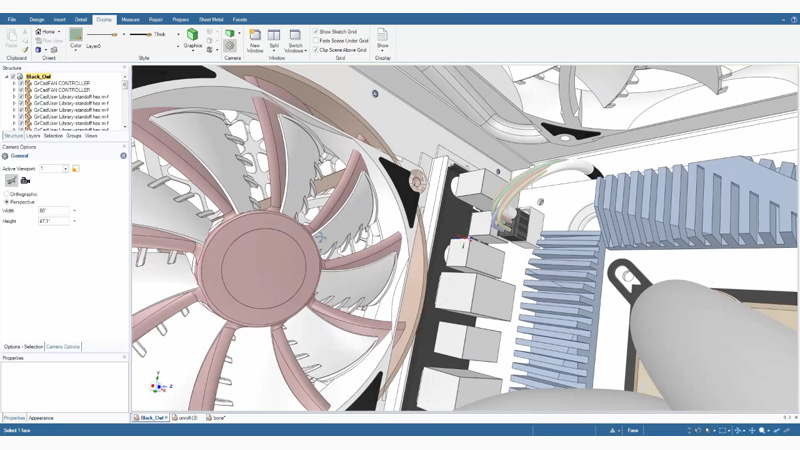

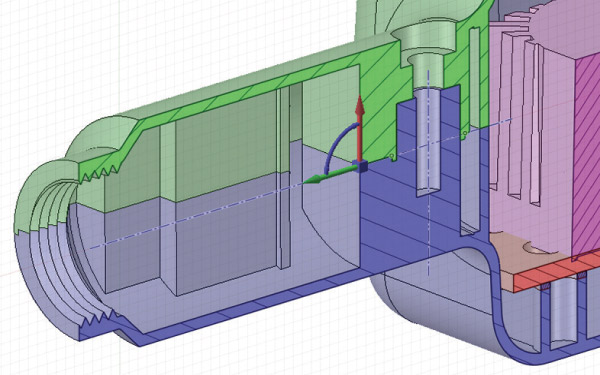

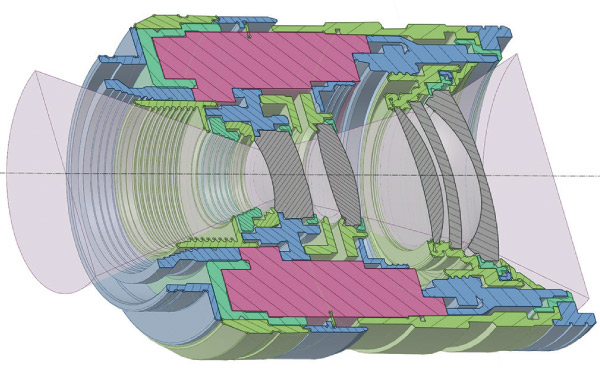

Visualize designs from the inside out. You can explore the inner details of a model without hiding components or using cross-sections. This capability provides graphical feedback at your fingertips while making it even more enjoyable to work in a 3D environment.

Watch Video

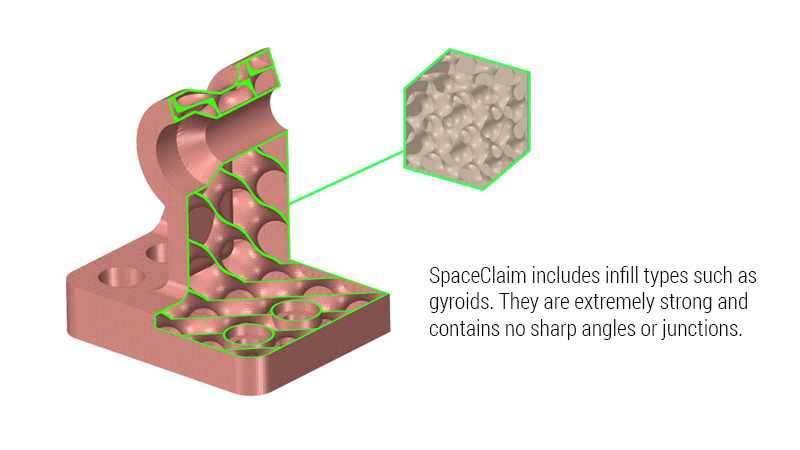

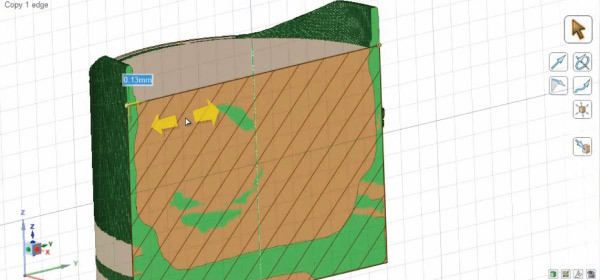

Lattice structures produce lighter, stronger, and better 3D printed parts. Discovery SpaceClaim makes it easy to create these types of structures inside of your part. When you are shelling, you can specify an infill for your part and select from several lattice infill types. Custom options (density, thickness, face selection) ensure your 3D printed component has an ideal strength-to-weight relationship.

Watch Video

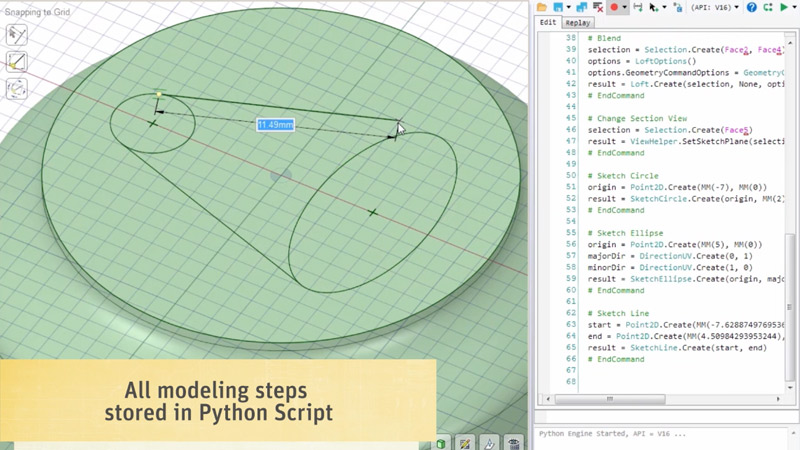

Discovery SpaceClaim commands include macro-like recording feature. Perform an array of edits on model, and Discovery SpaceClaim will record the necessary script. The data captured is in the Python language, so you don’t need to be proficient in scripting code or programming. Scripts can also be replayed on imported versions of a model. You can record the initial changes to a version of a model, then intelligently apply scripted changes to later versions of any file.

Watch Video

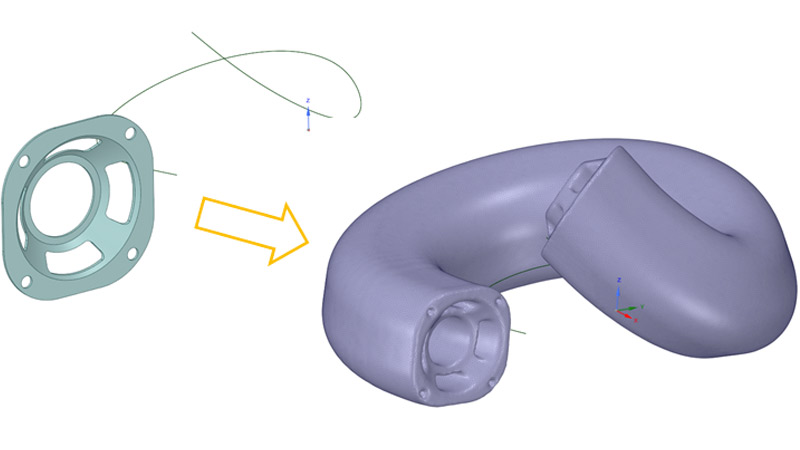

This functionality can take a solid body and sweep it along an arbitrary path. The result is a faceted body that is useful for creating and visualizing motion paths or envelopes, or for creating cuts from the path of a moving tool bit in machining operations.

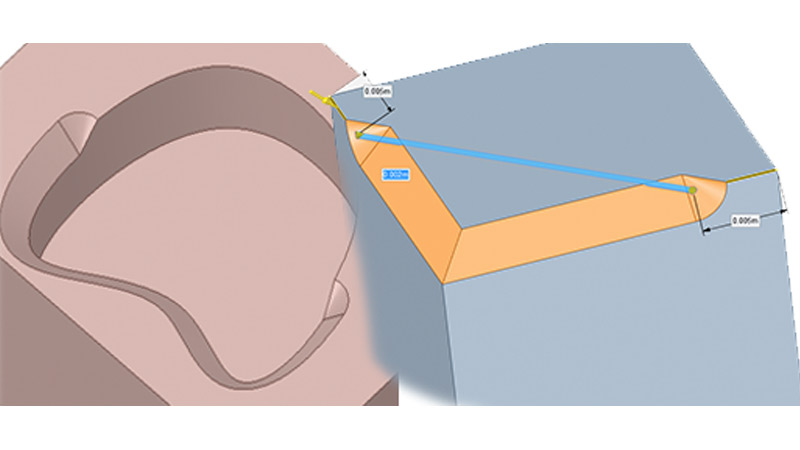

Stop chamfers give you the ability to stop a chamfer before reaching the end of an edge. With several parameters to select, this tool makes it easier to model real world parts.

This features is useful for flattening complex sheet metal design or modeling surface skins. With a single mouse click, you can unflatten a design into a 2D surface. Discovery SpaceClaim can handle multiple connected faces for flattening.

Discovery SpaceClaim is available through the following bundles: (1) ANSYS Discovery Essentials (includes only Discovery SpaceClaim); (2) Discovery Essentials + STL Prep for Printing Module; and (3) Discovery Standard bundles.

Discovery Essentials |

Discovery Standard |

||

|---|---|---|---|

| Discovery SpaceClaim |

Discovery SpaceClaim + STL Prep for Printing |

Discovery SpaceClaim + STL Prep for Printing + Discovery Live |

|

Discovery SpaceClaim

|

|

|

|

STL Prep for 3D Printing Module

|

|

|

|

Discovery Live

|

|

||

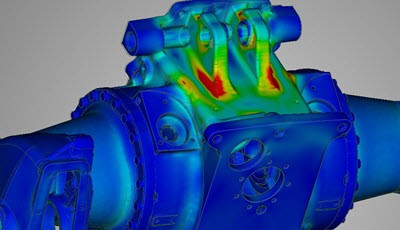

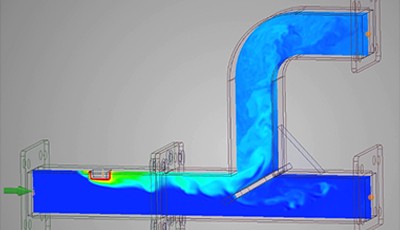

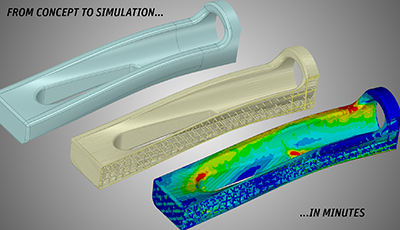

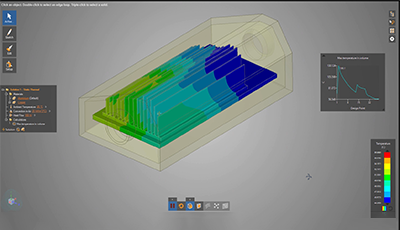

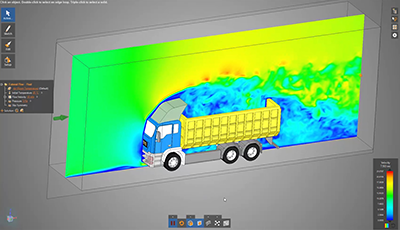

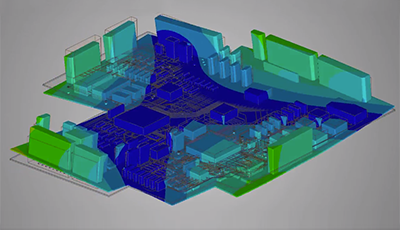

ANSYS Discovery Live is the first ever simulation environment that provides real-time answers to engineering challenges. Interact with your design by testing physics inputs and instantly see how your design performs under these parameters. Accelerate your product development, help avoid delays, and be sure you are designing the best products possible.

Test several design ideas in a few seconds. Receive immediate insight around the structural performance of a design.

Instantly find flow trends, even while changing geometry characteristics.

Remove material, retain strength, and discover how well your design will perform.

Instantly know how changes to models, heat input, or new materials will affect the thermal performance of your design.

Engineering simulations are instantaneous. Observe velocity, external forces, pressure, flow lines, particle flow, and more.

Observe different modes of vibration, make changes to geometry, and instantly evaluate performance.

SpaceClaim’s optional STL Prep for 3D Printing module prepares models for 3D printing efficiently. It’s a single solution that not only repairs problems, but also modifies STL and CAD files.

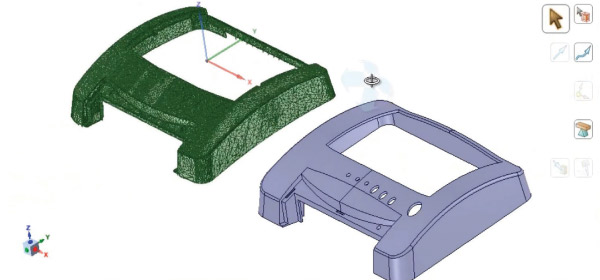

With Discovery SpaceClaim, you can create CAD models using 3D scan data. This is especially valuable when the original design documents are no longer available and you need to reproduce the part or build a new product (ie. accessory, case) using a part’s measurements.

SpaceClaim is the perfect solution for handling STL files to:

The Skin Surfacing tool gives you a powerful method for autosurfacing to surface or solid geometry from prismatic or organic shapes. It can also be used to reconstruct fixtures or jigs around faceted data, or to modify geometry of things like worn out parts.

Gain greater efficiency within SpaceClaim’s reverse engineering workflow to:

Discovery SpaceClaim enables engineers to quickly and easily visualize, communicate, and evaluate designs in 3D for product design and development.

Learn how SpaceClaim became Michael McGinnis’ go-to CAD modeling software to design his award-winning toy, Perplexus.

In contrast to the confines of history-based concept modeling and its complexities, SpaceClaim gives you the freedom to focus on the creative process and not on the technology.

“Within two days of actually implementing SpaceClaim, we were up and running and actually making very complex models.”

Gene Garbaccio COO, 3Discovered